Polyisocyanurate Insulation: What Is the R-Value and 10 Other Common Questions About Polyiso Insulation Answered

There are many different kinds of insulation in the market, made by several different manufacturers. Some of the most commonly known insulations include fiberglass batt insulation, expanded polystyrene (eps roof insulation), which is typically white and often used in eifs, extruded polystyrene (xps), which is typically blue or pink and commonly used in masonry applications, and mineral wool insulation. The most common type of building insulation is polyisocyanurate (polyiso) insulation, used in both roof and wall applications. This article will explore some of the most common questions about polyiso insulation.

1. What Is Polyiso Insulation?

Polyisocyanurate insulation is a rigid, closed cell, continuous foam board insulation. Closed cell foam is made of uniform cells that are “closed.” The “closed” cells are pressed together, so air and moisture are unable to get in between the cells or inside the foam. Rigid polyiso insulation board is sandwiched between two facers that can offer unique performance characteristics (see question 11 below) and provides top-of-class insulative properties. Among its other properties, polyiso has:

- The highest R-Value per inch of commonly used insulations.

- A moisture-resistant foam core.

- Compatibility with most solvents used in construction.

- Excellent dimensional stability.

- Excellent performance in fire tests for both roof and wall applications; polyiso meets the strict standard of both FM Class 1 Approvals (FM 4450/4470), UL 1256, CAN/ULC S126M and NFPA 285 testing.

- A CFC- and HCFC-free product with zero ozone depletion potential and negligible global warming potential.

- Recycled content in most products (see manufacturer for details).

2. Can Polyiso Be Used for Both Roof and Wall Insulation?

Absolutely. Polyiso is the most popular choice for insulation in new commercial roofs and reroofing projects.

The Atlas ACFoam line of polyiso insulation is designed specifically for roofing projects. It’s compatible with nearly all commercial roof systems including built-up (BUR), modified bitumen, metal, ballasted single-ply, mechanically attached single-ply and adhered single-ply.

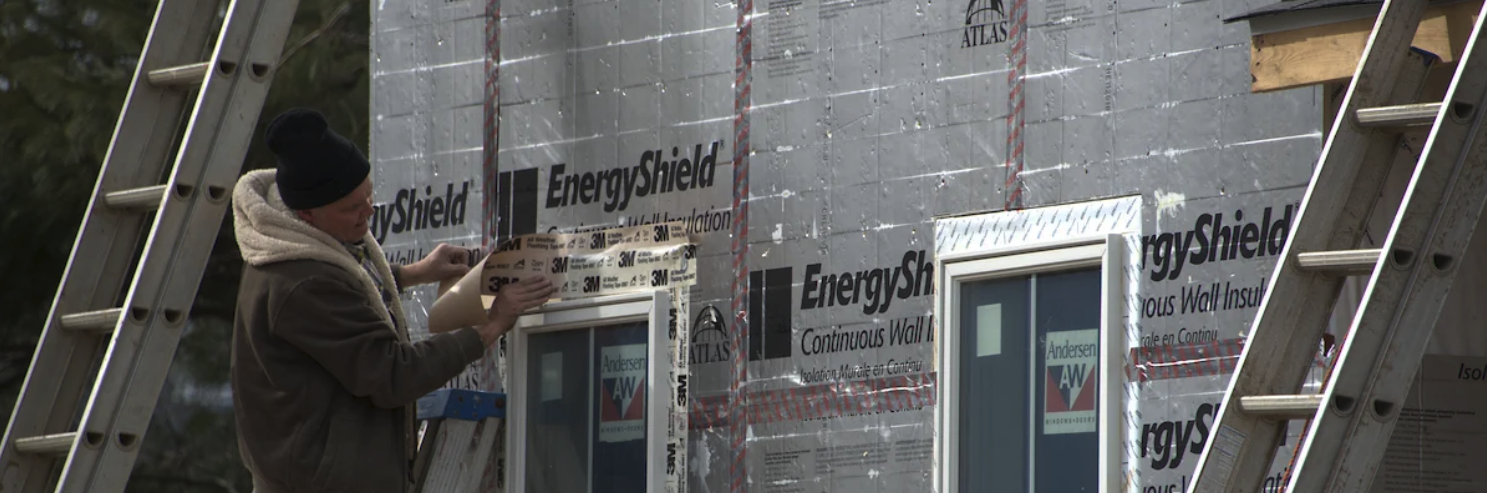

Polyiso insulation is also a popular choice for wall insulation. Atlas EnergyShield products are designed specifically for wall insulation needs. By using polyiso insulation on walls, builders, designers and architects can create exterior continuous insulation, which is the most effective way to insulate building envelopes for energy savings.

Atlas EnergyShield wall insulation products are made with a polyiso core, which achieves a higher effective R-value (the capacity to resist heat flow) with minimal material thickness. Plus, Atlas EnergySheild products can be used in basements, attics doors and crawl spaces.

3. What Is the R-Value of Polyiso Insulation?

R-value refers to the thermal resistance of a material. Polyiso insulation is unique among rigid foam insulation options in that its R-value per inch increases as the material gets thicker. For example, the R-value of two inches of polyiso insulation provides more than double the R-value of an inch of the same product.

When comparing thermal resistance characteristics of polyiso foam, the Polyisocyanurate Insulation Manufacturers Association (PIMA) recommends the use of LTTR (long-term thermal resistance) for permeability faced polyiso roofing insulation. The LTTR value (thin sliced method) is a 15-year, time-weighted average of the foam’s R-value.

For the R-value of polyiso wall insulation, a full thickness, 180 day aged value is recommended. Foilfaced polyiso has an R-value of about 6.5 per inch and permeability faced polyiso wall insulation has an R-value of around 6.0 per inch. For more exact values, please click here to check out our data sheets.

4. Is Polyiso Environmentally Friendly?

No insulation offers better long-term energy savings than polyiso. Because of its high R-Value, polyiso significantly reduces the environmental impact that buildings have on the environment. In addition, Polyiso insulation is manufactured using a lowimpact process resulting in an environmentallyfriendly product.

Atlas Roofing Corporation manufactures its polyiso insulation with third-generation, zero ozonedepleting blowing agents and with zero Global Warming Potential (GWP). All Atlas Polyiso products have long been HCFC-free and CFC-free. According to PIMA, virtually all polyiso manufacturers use recycled raw materials, as well as recycled organic materials in their facers.

Both Atlas’ EnergyShield and ACFoam product lines are GREENGUARD and GREENGUARD Gold certified. And all of our foil and coated glass faced products are UL Microbial Resistant certified.

Because Atlas is committed to environmental responsibility, in June 2019, Atlas announced the addition of non-halogenated products to both the EnergyShield and ACFoam product lines. These new products contain no halogenated flame retardants, providing additional environmentally-friendly options to their product offerings of sustainable roof and wall insulations. You can read more about these new products by clicking here.

Polyiso also is an effective insulation solution for architects and contractors working on net-zero and passive building projects. With its low environmental impact during manufacturing and its potential to help reduce fuel requirements for building heating and cooling, polyiso insulation can help building owners gain points in multiple areas under the LEED program.

5. Can Polyiso Be Used for Residential Construction?

Polyiso wall insulation is one of the best values available for new residential construction and remodeling. Homeowners will enjoy:

- High R-value, leading to improved energy efficiency resulting in improved cost savings on their utility bill.

- Integrated air barrier resulting in improved HERS ratings

- Vapor management to avoid problems with condensation and moisture intrusion.

- Fewer thermal breaks. This results in less energy loss and a more uniform comfort level.

6. Is Polyiso Insulation Fireproof?

Polyiso insulation has superior fire resistance compared to other types of rigid foam insulation. As a thermoset material, polyiso has the benefit of forming a protective char layer. By comparison, other types of foam insulation are thermoplastics and melt when exposed to a heat source, dripping onto surfaces below, increasing the potential for damage.

Atlas Polyiso has been extensively tested to prove building code and product standard compliance. For additional information, click here.

7. How Does Polyiso Compare to XPS Foam Insulation?

When considering rigid foam insulation options, many contractors and designers will compare polyiso with extruded polystyrene (XPS). XPS is a thermoplastic which means it melts when exposed to heat source. By comparison, polyiso is a thermoset material and exposure to heat will not cause it to melt. Polyiso chars over in a fire, while XPS insulation melts and drips.

Polyiso offers greater R-value per inch, meaning wall and roof assemblies can be thinner. The moisture resistance of Polyiso is equivalent to XPS. Polyiso offers products suitable for a variety of vapor control strategies, whereas XPS offers limited vapor permeability options. Polyiso also offers a wide variety of added benefits related to its variety of facers options.

Polyiso is sandwiched between two layers of organic or inorganic facers that offer other benefits such as moisture-resistance or enhanced adhesion. Whereas XPS is limited to one facer type, offering limited benefits.

8. How Does Polyiso Compare to Mineral Wool Insulation?

Mineral wool’s R-Value per inch is approximately one-third lower than polyiso.

Polyiso offers compressive strength options from 20-25 psi and some coverboards up to 110 psi, whereas Mineral Wool has a psi range of 5-11.

Mineral wool is made from molten glass, stone or slag and other raw materials, which are then heated and spun into very thin fibers and held together with binders. It can be formed into long blankets, making it an option for continuous insulation.

Polyiso and Mineral wool can both be used in a wide variety of fire rated and code-compliant assemblies.

For designers looking for the best option to meet energy conservation goals, polyiso is the most popular choice.

9. Is Polyiso Insulation Water-Resistant?

Yes. The hydrophobic core of polyiso makes it exceptionally water-resistant compared to other rigid foam insulation products on the market. Additionally, the facers used to cover both sides of a polyiso insulation board can further enhance its moisture resistance.

10. What Are the Most Common Types of Facers for Polyiso Insulation and What Do They Do?

Polyiso is an incredibly durable, strong and chemical resistant material. But one of the unique features of polyiso insulation is that it comes sandwiched between layers of facing. These thin organic and inorganic sheets offer a number of additional benefits that make polyiso an even more attractive option to designers and builders. Facers include:

- Non-asphaltic, fiber-reinforced organic felt facers, like those on ACFoam-II. These are the standard facers for roofing, but they are not used in wall products. They provide economical and lasting performance and are compatible with a wide variety of roof membrane assemblies. Inorganic coated glass facers, like those on ACFoam-III, ACFoam HD Cover Board, EnergyShield CGF and EnergyShield CGF Pro, are significantly more durable and are chemical and mold resistant.

- Foil facers, like those in EnergyShield, EnergyShield Pro and ACFoam Supreme, provide increased dimensional stability as well as decreased potential for water absorption and water vapor transmission.

11. How Do I Store Polyiso Insulation?

While polyiso is strong and water-resistant, if you won’t be installing it right away, you’ll want to make sure it is stored properly. If you are storing your insulation outside or on the job site, make sure the insulation is stacked on pallets at least three inches above ground level and completely covered with a weatherproof covering such as a tarpaulin. Polyiso insulation shouldn’t be stored outside for more than two weeks. If it needs to be left on a job site for longer, it should be kept indoors in a well-ventilated area.

Factory-applied packaging is intended only for protection during transit. The temporary factory-applied packaging should be slit or removed to prevent accumulation of condensation when being stored.

Be sure to check the manufacturer’s storage recommendations.

Even if you’re only storing your polyiso insulation outside for a short amount of time, make sure it’s properly secured. Like all foam products, polyiso is relatively lightweight and can easily blow around if it isn’t weighted down.

More Questions?

For more information on polyiso insulation, and to find the product that’s right for your next project, visit the Atlas Roof & Wall Insulation website.