When any company talks about their global footprint, they often do so in terms of transportation pollution (i.e., the greenhouse gases emitted while transporting goods along the supply chain) and recycling (i.e., how products are responsibly disposed of after their useful life). At Atlas, we believe reducing our global footprint extends beyond limiting the impact our products have on the environment while they are in transport or after they are used. We focus on limiting our products’ environmental impact during the manufacturing process as well as their time in use on the building.

Why Indoor Air Quality Matters

The national conversation about air quality often revolves around the air we breathe when we are outside. Americans, however, spend the bulk of their time inside, whether it is at home, work, school, or elsewhere. According to the National Human Activity Pattern Survey (NHAPS) published by the Lawrence Berkeley National Laboratory, people spend the vast majority of their lives – 87 percent of it – indoors. This study — conducted among thousands of individuals across 48 states in the continental U.S. — illustrates how people are generally more vulnerable to indoor pollutants than pollution found in outdoor environments.

According to the Environmental Protection Agency, indoor pollutants can aggravate asthma, allergies and chronic respiratory or pulmonary diseases, especially among vulnerable populations. This is particularly concerning for schools, as the developing bodies of children may be more susceptible to indoor exposures than those of adults, given that children breathe more air, eat more food and drink more liquid in proportion to their body weights. Despite this, 50 percent of U.S. schools report poor air quality, and much of it has to do with poor building product choices.

To top off these concerns, volatile organic compounds (VOCs) – a broad class of man-made and naturally occurring chemical compounds emitted as gases from various products – are found in concentrations up to 10-times higher in indoor environments than outdoors. This high concentration is typically due to the organic solvents found in various paints, varnishes, waxes, adhesives and fuels, as well as many cleaning, cosmetic, and building products used in homes, offices and schools. VOCs may cause headaches and eye/nose/throat irritation in the short term and contribute to chronic diseases, including cancer, over long term exposure.

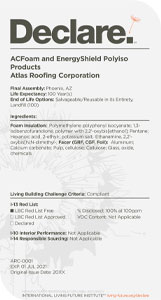

Despite this, there are no federally enforceable standards limiting VOCs in non-industrial settings. That is why it is important for specifiers to choose building materials that don’t contribute to poor air quality, such as Atlas EnergyShield products, many of which are GREENGUARD Gold-certified. These products meet or exceed the highest state and federal restrictions on VOC emissions. Atlas has also introduced new non-halogenated products to its EnergyShield product line, which offer the same great performance but contain no halogenated compounds (e.g. fluorine, chlorine, bromine, iodine or astatine). Atlas Non-halogenated products provide options for architects and specifiers to meet certain environmental specifications set by governments, companies and cities. EnergyShield non-halogenated products also carry the International Living Future Institutes’ Declare label, a brand promise for building products that informs consumers about a product’s VOC content, life-expectancy, chemical composition and other important health information.

Building Materials and their Impact on the Environment

Atlas also considers the impacts its products can have on outdoor environments. Greenhouse gases (GHGs) released from the burning of fuels trap heat in the atmosphere, raising ambient temperatures as well as the temperatures of oceans. Thus, can negatively impact marine life, weather patterns and the food supply. It can also impact respiratory health by aggravating the effects of smog and air pollution. GHGs also contribute to the gradual thinning of the ozone layer, which protects life on Earth from harmful ultraviolet (UV) radiation produced by the sun.

According to the EPA, industry is responsible for 22 percent of all global GHG emissions, primarily from burning fossil fuels for energy and certain chemical reactions used in the manufacturing processes. The blowing agent used to produce the Polyiso insulation foam core of EnergyShield products does not contain any CFC’s, HCFCs, and HFCs, resulting in zero Ozone Depletion Potential and Negligible Global Warming Potential.

Furthermore, a study of building practices shows 6-8 percent of building project GHG emissions come solely from the transportation of materials. Atlas’ manufacturing footprint across North America can provide shipments within 500 miles or less of most job sites which can contribute to LEED qualification.

While industry standards are evolving to create products with fewer environmental impacts, the final say on which products are used often falls upon specifiers and architects. That is why it is important to consider building materials that impact the environment less. Atlas EnergyShield products create no GHGs during the manufacturing process and utilize up to 13 percent recycled content. Atlas utilizes its manufacturing footprint to decrease the contribution of GHG during transit. Finally, many EnergyShield products can be salvaged and reused at the end of a building’s life.

Additional Environmental Advantages of Using Polyiso Insulation Products

When choosing building insulation, it often comes down to a choice between a mineral wool product (fibrous material formed from the byproduct of crushed rock and/or ceramics) and polyisocyanurate, or polyiso, for short (a thermoset plastic typically produced as a semi-rigid foam). The popular assumption is that mineral wood is more environmentally sound because it is made from rocks rather than a type of plastic. Polyiso insulation products like EnergyShield continuous wall insulation, however, are lighter to transport, offer the highest thermal efficiency, and provide the best R-value in panel insulation (R-6.5 per inch). Offering the maximum R-value per inch of thickness means less total product is needed to achieve a specified R-Value, reducing overall construction costs and increasing building square footage.

Polyiso insulation also reduces the number of thermal bridges (walls studs and other conductors that allow heat to travel through a wall cavity) as it can be installed continuously over frames and joist without complex and thermally compromising mounting systems. This allows heating, ventilation and air conditioning (HVAC) systems to operate at maximum efficiency, reducing stress on the system and decreasing costs. A recent study by the Polyisocyanurate Insulation Manufacturers Association (PIMA) comparing initial embodied energy to long-term energy savings achieved over 60 years in a typical commercial building suggests that the net energy savings potential of Polyiso insulation wall insulation ranges between 20 and 47 times the initial embodied energy required to produce, transport, and install the product; making Polyiso insulation a smart environmental choice over the lifetime of a building.

Atlas believes buildings can and should be designed to a higher environmental standard regardless of the minimum code requirements. When building with the environment in mind, thoughtfully manufactured Polyiso insulation products like EnergyShield can be part of the solution for designing healthier buildings.