Fire resistance performance is a critical component for any roofing system. All roof assemblies must meet or exceed building code requirements, including both the International Building Code (IBC) and local jurisdictional code requirements, as well as project specifications.

Underwriters Laboratories (UL) subjects roof assemblies to standard testing methods to determine fire resistance performance and ratings. Both combustible and noncombustible roof deck assemblies must be evaluated per the UL 790 (ASTM E108) Standard Test Methods for Fire Tests of Roof Coverings, which exposes a roof assembly to simulated fire originating outside the building accompanied by wind conditions. It is important to know that Class A roof coverings are effective against severe fire test exposures, Class B roof coverings are effective against moderate fire test exposures and Class C roof coverings are effective against light fire test exposures.

Testing methods for Classifications over combustible and noncombustible decks

For combustible roof deck Classifications and noncombustible roof deck Classifications, flame spread on the top surface is evaluated (the Spread of Flame test). Since steeper slopes present more challenges due to increased flame spread propagation, the test slope is preselected and the final rating applies to the maximum slope passed. To obtain a Class A rating, flame spread cannot exceed six feet during the 10-minute test.

Combustible deck Classifications, such as over OSB or plywood, however, require two additional tests – the burning brand test and the intermittent flame test. For the burning brand, an ignited wood lattice (or brand) is placed on the test specimen. For Class A, the brand weighs 2,000 grams. Successful results are obtained if there is no sustained flaming of the underside of the test deck, and burning or glowing particles do not fall to the floor and continue to burn or glow. Four consecutive passes of the 1.5-hour burning brand test are required to achieve a Class A rating.

For the intermittent flame test, a variable flame source is cycled on and off on the test assembly. The conditions for this test are similar to those in the Spread of Flame Test, but the test assembly must resist 15 cycles to achieve a Class A rating. Successful results are obtained if there is no sustained flaming of the underside of the test deck, and burning or glowing particles do not fall to the floor and continue to burn or glow. Two consecutive passes of the 2-hour intermittent flame test are required to achieve a Class A rating.

Four ways to achieve UL Class A with Atlas Roofing products

Atlas has several ACFoam® roof insulation products that can be used to help achieve a Class A fire resistance rating for a roofing assembly installed over combustible wood roof decks. These four designs offer a variety of options to meet the project needs of architects and specifiers.

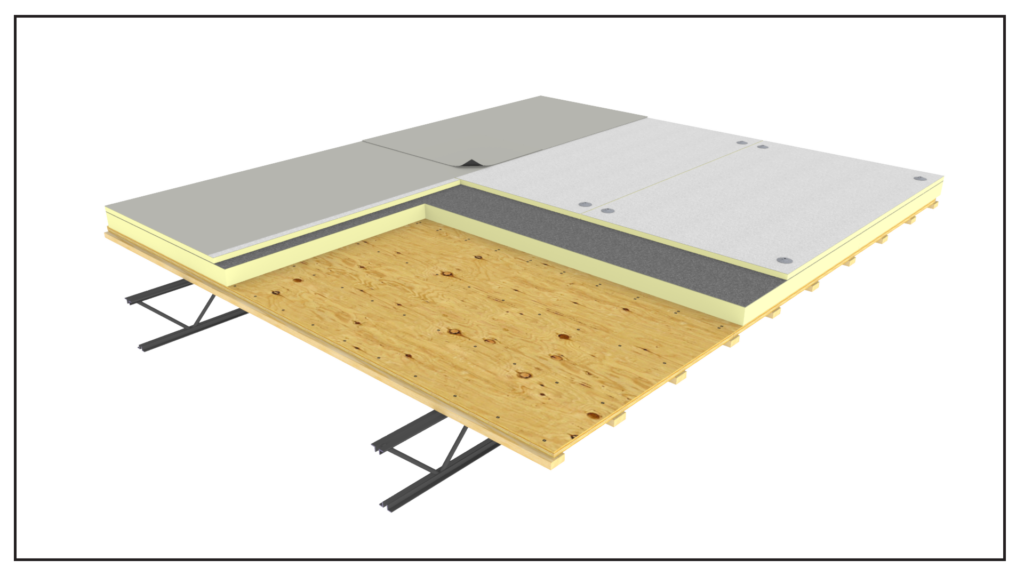

Option 1: ACFoam-HD CoverBoard-FR, with optional ACFoam-II, ACFoam-II NH, ACFoam-III or ACFoam-III NH

ACFoam-HD CoverBoard-FR, the newest addition to the ACFoam product line, is a lightweight coverboard insulation that can be used in one layer alone or with an optional layer of ACFoam-II, ACFoam-II NH, ACFoam-III or ACFoam-III NH, along with approved membranes, on a wood roof deck to achieve a UL Class A rating. The one layer saves users both labor and materials.

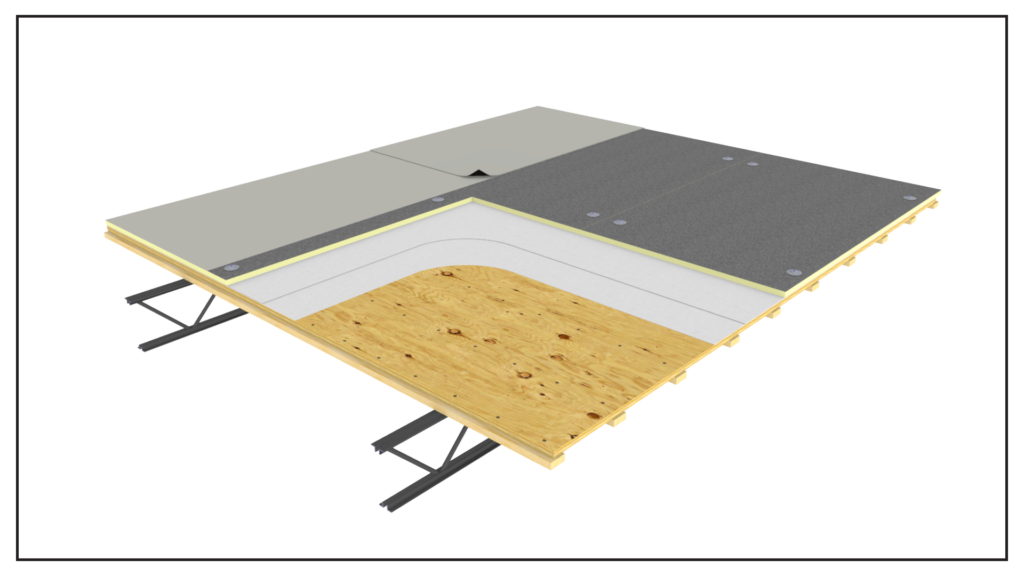

Option 2: Two layers of FR-10 Fire Retardant Slipsheet

FR-10 is a coated-glass fiber mat designed for installation over wood decks. You can use two layers with approved membranes on a combustible deck for a Class A rating.

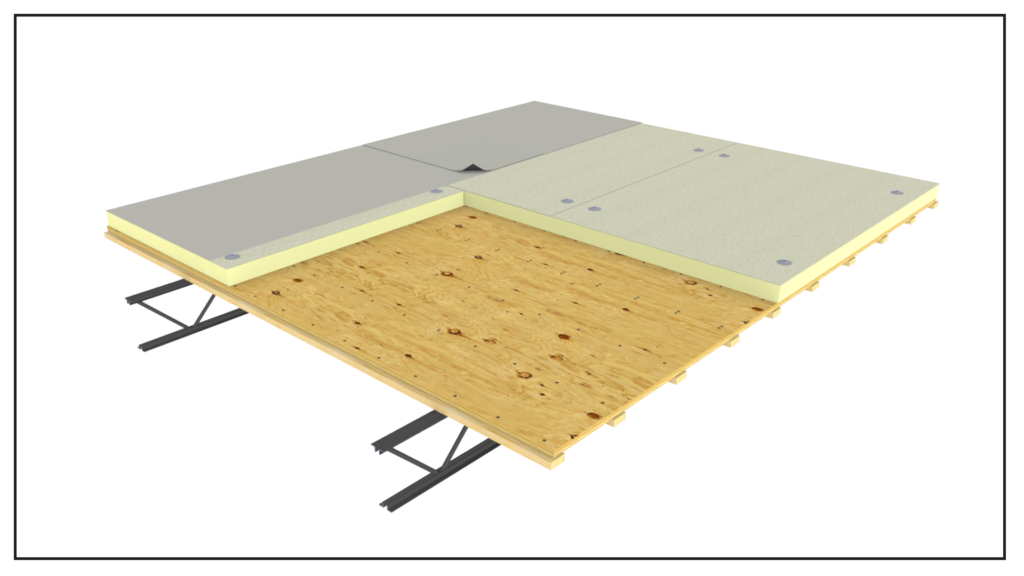

Option 3: 3” layer of ACFoam-III or ACFoam-III NH or two layers 1.5” ACFoam-III or ACFoam-III NH

Our ACFoam-III and ACFoam-III NH insulation can be used with approved membranes as part of a Class A assembly. You can apply a 3” layer or two 1.5” layers.

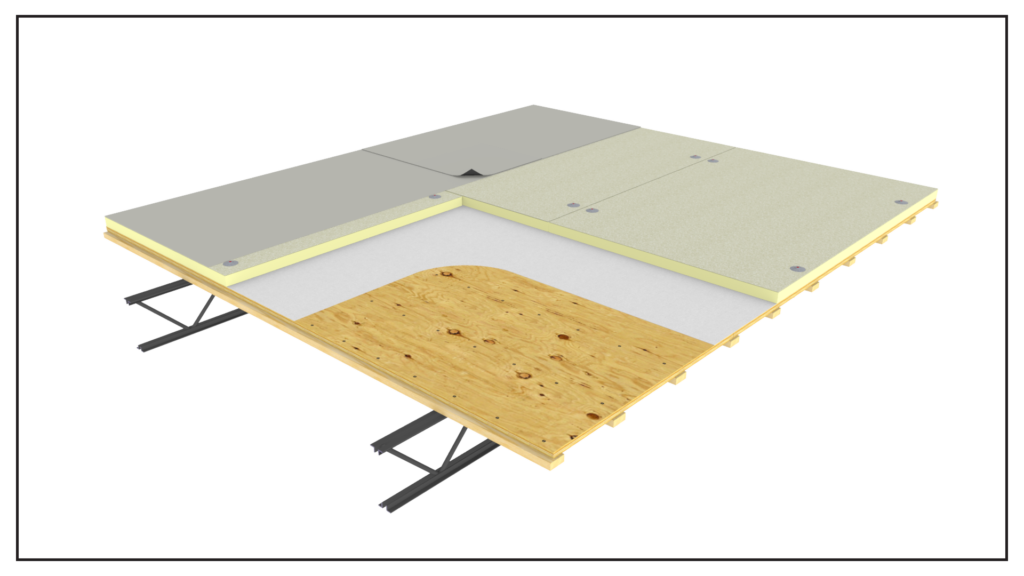

Option 4: FR-10 Fire Retardant Slipsheet + 1.5” ACFoam-III or ACFoam-III NH

A combination of Atlas FR-10 Fire Retardant Slipsheet and 1.5” ACFoam-III or ACFoam-III NH can be used with approved membranes to achieve a Class A rating.

To find out more details and specifications for each of these assemblies, view our UL Class A product selector, or refer to UL Product iQ; Atlas Roofing Corporation UL Category Code TGFU File Number R13089; or contact the Atlas Roofing Corporation Technical Department.

Multiple Solutions from Atlas

Atlas is here to help customers find the optimal solution to achieve a UL Class A fire resistance rating for a roofing assembly installed over a combustible wood roof deck. If you’d like to learn more about ACFoam-HD CoverBoard-FR and all your Class A product options, contact your local Atlas sales representative.